ERMA FIRST FIT 2000

- Admin

- Jun 15, 2025

- 3 min read

Updated: Jun 16, 2025

⚙️ How ERMA FIRST FIT 2000 Works – Full Guide for Pump-In and Pump-Out

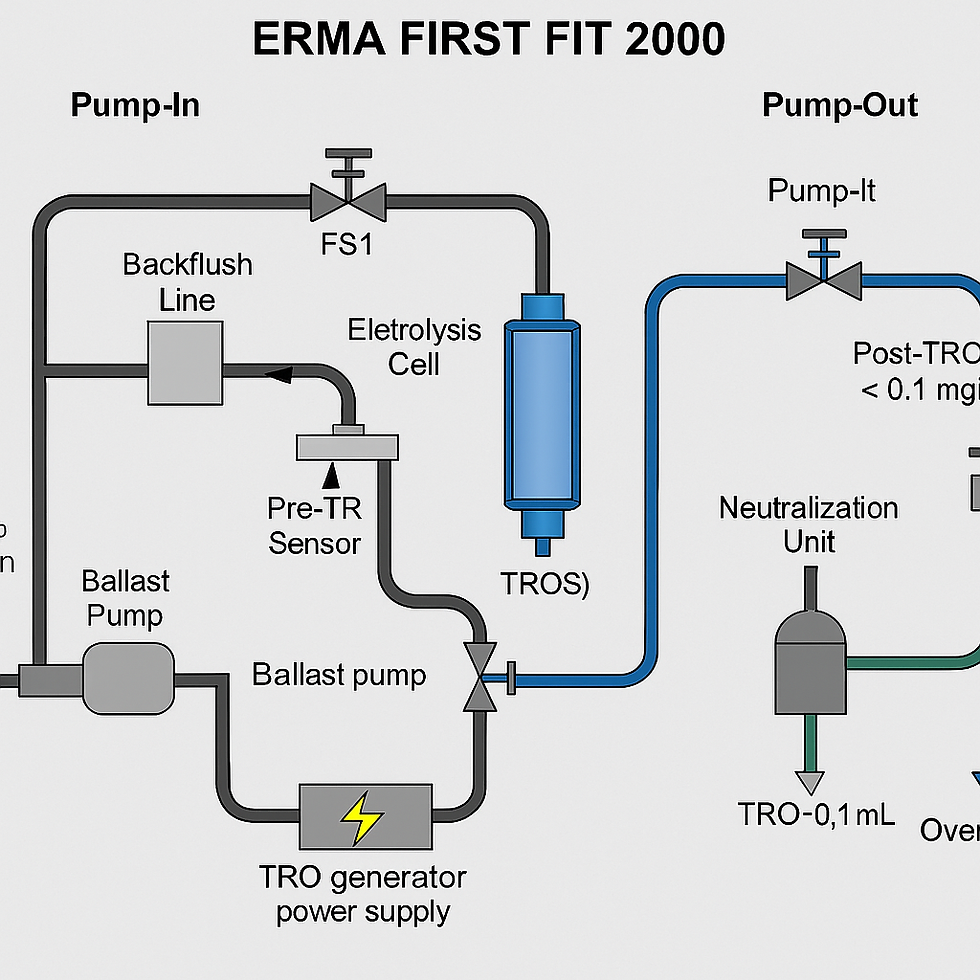

The ERMA FIRST FIT 2000 is a filtration + electrolysis ballast water treatment system approved by IMO and USCG. It is designed to eliminate invasive marine species during both ballasting and deballasting operations.

Here is a clear, step-by-step explanation of how the system works during Pump-In (ballasting) and Pump-Out (deballasting), based on official system documentation .

🧭 System Overview – Key Components

Component | Function |

Sea Chest Suction | Water intake during pump-in |

Backflush Line | Used to clean filters during backflushing |

Filter Unit | Removes particles > 50 µm |

Electrolysis Cell (TROS) | Produces oxidants (NaOCl) from seawater |

TRO Sensors (TR0-1, TR1) | Measure oxidant concentration before and after injection |

Neutralization Unit | Adds sodium thiosulfate to remove residual oxidants during pump-out |

Control Valves | Automatically open/close based on mode |

Flow Meter (FM1) | Measures treated water volume |

TRO Generator Power Supply | Provides voltage and current to TROS |

Discharge to Tank/Overboard | Direction of treated water |

🔄 Pump-In Operation (Ballasting)

During ballasting, the system performs filtration + disinfection using electrolysis.

🧪 Treatment Steps:

Seawater Intake

Ballast pump draws water from the sea chest

Enters system through open suction valve

Flow Measurement

Water passes through Flow Meter (FM1)

TRO Pre-Sensor (TR0-1) checks oxidant in raw water (normally ~0)

Filtration

Water flows into Filter Unit

Particles and organisms >50 µm are removed

Differential pressure is monitored to detect clogging

Electrolysis Disinfection

After filtration, water enters Electrolysis Unit (TROS-1-L)

Sodium hypochlorite (NaOCl) is generated onboard via electrolysis of seawater

No chemicals are stored or dosed externally

TRO Monitoring

Water passes through Post-TRO Sensor (TR1)

Checks that TRO is within 1.0–2.5 mg/L

If outside limits → alarms & shutdown possible

Flow to Ballast Tanks

Treated water is discharged to selected ballast tanks via valve V1.03

🔁 Pump-Out Operation (Deballasting)

During deballasting, the system performs TRO neutralization before overboard discharge.

🧼 Neutralization Steps:

Tank Water Suction

Water is drawn from ballast tanks

Enters the treatment system via pump

Flow Monitoring

Water passes through Flow Meter (FM1)

TRO Check

Pre-TRO Sensor (TR1) measures oxidant level in tank water

If above 0.1 mg/L TRO → Neutralization system activates

Neutralization

Sodium thiosulfate is injected automatically

Converts NaOCl into harmless salts

Ensures no oxidant reaches the environment

Overboard Discharge

Water is discharged overboard via open valves

Final Post-TRO Sensor ensures TRO < 0.1 mg/L (USCG limit)

🧠 TRO – What It Is and Why It Matters

TRO (Total Residual Oxidant) = concentration of oxidants (mainly hypochlorite) used to disinfect water.

Generated onboard by electrolysis

TRO during pump-in:✅ Normal = 1.0–2.5 mg/L

TRO before pump-out:Must be reduced to < 0.1 mg/L by neutralization

⚠️ High TRO without neutralization = port violation risk

⚠️ Low TRO during ballasting = ineffective treatment

🛠️ Alarms and Safety

TRO Deviation Alarm – triggered if values outside safe limits

Pressure Alarms – triggered if filter clogging or bypass needed

Bypass Only Possible if inlet water meets clarity standards

System must flush before standby or shutdown

✅ Crew Best Practices

Always monitor TRO levels and electrolysis current/voltage

Confirm correct valve status in Ballast or Deballast mode

Log flow totals and TRO data

Conduct pre-port tests during drills

Never isolate key valves (V1.03, neutralizer line) manually

📌 Final Reminder

ERMA FIRST FIT 2000 uses automated electrolysis chlorination during pump-in, and chemical neutralization during pump-out. Both must be correctly monitored to meet IMO/USCG discharge criteria.

⚠️ Always follow your vessel's SMS, the official ERMA FIRST manual, and port authority instructions.

1 Comment